Multistage gearbox failure

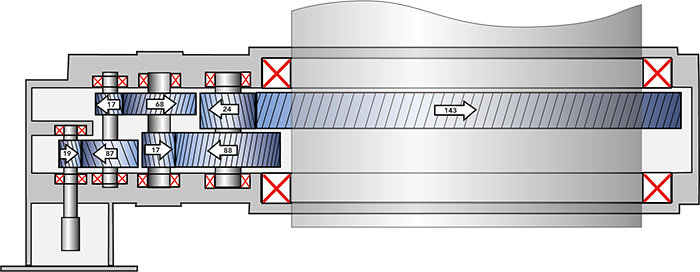

Part of a comprehensive project investigating and determining best practices for gearbox monitoring with HD technology, this case study involves condition monitoring of a multi-stage gearbox in a pulp mill.

The four-stage gearbox was in good condition when measurements began; over time, however, the monitoring system started to indicate problems. Since both bearing and gear condition were deteriorating in the course of the monitoring period, the installation provided an excellent opportunity to evaluate which measuring technique and measurement configurations work best on gearboxes.

Based on the clear measurement results, the root cause analysis showed that the damage to bearings and gears occurred as a result of water penetrating the gearbox.

Download full case study

Case Study

CS020 - Multistage gearbox failure| Filename/description | Language | Size | Modified | |

|---|---|---|---|---|

| CS_020B_GearboxFailure_SE.pdf | English (United Kingdom) | 7 MB | 5/25/2018 | |

| Multistage gearbox failure - Root cause analysis and recommendations for gearbox monitoring with HD technology. | ||||